From high-quality products to and services like Hot tapping, Intelligent pigging, pipeline cleaning, Advance Geometry inspection, debris mapping, pipeline profiling capabilities ensure every job is successfully completed to exact customer expectation

Intelligent pigging

Onsite reporting, Dent verification

Pipeline cleaning

Pig signaler & Pig tracking Device

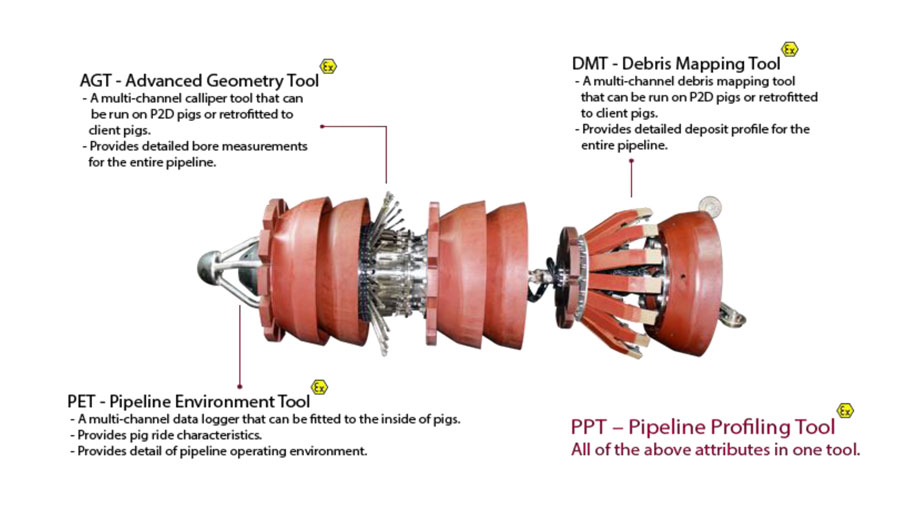

Advance Geometry Inspection

Debris Mapping

Pipeline Mapping tools

Pipeline environmental tools

Typically, most of the pipelines uses MFL(Magnetic Flux Leakage ) technology for inspecting these pipelines for monitoring corrosion and any external damage to the pipeline. We offer range of tools for inspecting pipelines and also provide FFP (Fitness for Purpose) which means safe operation of the pipeline.

The purpose of using these Intelligent pigs is to identify any type of Metal loss/Corrosion in the pipeline which can cause the pipeline to fail.

We offer complete solution in association with our technology partner who provides us tool, and data analysis with reports. We help customer here to identify technology required, asses the condition of the pipeline, provide them with solution as to what is the best technology required to inspect their pipelines. We can support for the tools ranging from 4” to 48”.

We also have technical support for providing Fitness For Purpose report after the Intelligent pigging is carried out and report is provided. We can provide FFP report based on Intelligent pigging report and data and can provide recommendation for repairs based on the intelligent pigging data.

We also offer onsite dig verification services post Intelligent pigging report. This helps the Pipeline operators to verify the report provided by Intelligent pigging and compare result with actual finding on site. This helps customer to actually make a decision on the repairs to be carried out.

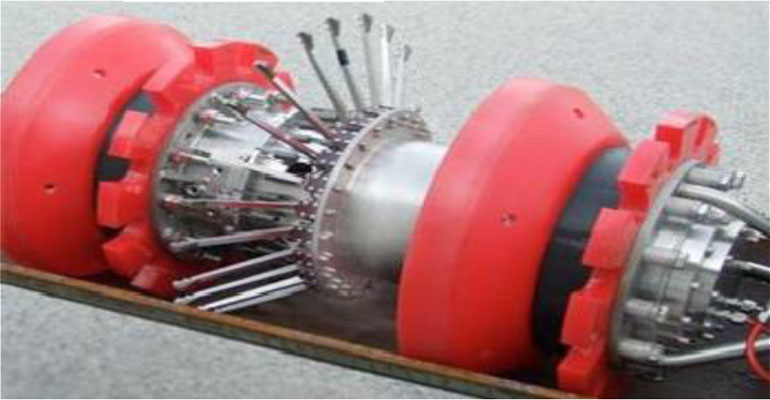

A Configuration of in-line inspection tool designed to record geometric conditions of pipeline such as Dents,buckels, wrinkles, ovality, bend radius and angle, and occasionally, indications of significant internal corrosion by sensing the shape of the internal surface of the pipe.

Our Advance Geometry tools finger arm mounted with advance sensing sensors make direct contact with pipe wall and covers circumferentially 360 degree of pipe circumference. Any change in Diameter of pipeline can sense by arm movement and recorded into on board electronics unit for further Analysis. High accuracy Odometers are in placed to record axial distance of pipeline for any defect identification on pipeline axis.

Our technology partner for advancement in Configurations of tool, application engineering, technical support, software and data analysis is www.pipelines2data.com .

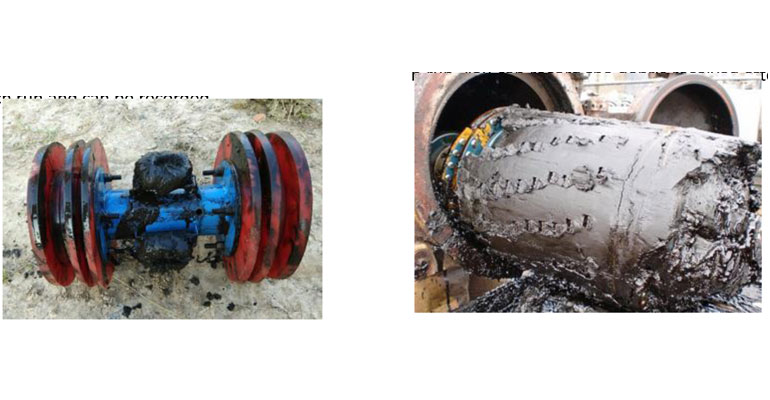

We offer services for routine maintenance programs where we can design pigging programme to suit the pipeline conditions by knowing history of pipeline, pigging program adopted, and types of pigs used for carrying out the programs. After detailed study and considering all parameters, an appropriate cleaning program including the right and proper selection of cleaning pigs. We provide detailed cleaning program with operational support including pig launching, pig receiving and pigs tracking and data collection etc. The cleaning progress and effectiveness can also be monitored, and we can really design complete pigging solution that is needed for that particular pipeline.

The best method of cleaning the pipeline is using pigs and different types of pigs can be used to cleaning the pipelines with different mediums The first pig to put in the pipeline is foam pigs. The low density, medium density an high density foam pigs can be used to start the operations which will establish pipeline pigability. Upon receiving the foam pigs and depending upon the condition of foam pigs , further pigs can be launched. The pigs to be launched can be brush pigs, batch pigs and disc pigs to push the debris loosen by the brush pigs. You can also couple two pigs to get better and effective cleaning, this is called coupled pigs. This operation can be continued for no of runs and every run you can evaluate by measuring debris coming out after each run. You can record the debris received after each run and can be recorded

We know the importance of pipeline pig tracking and locating as well as signaling of pig passage.

We can supply and install pig signaler both intrusive type as well as non intrusive type.The customization of intrusive type pig signaler is possible based on customer requirement. We can also supply pig tracking device and can provide service of pigtracking as well.

Quantify the thickness, distribution and potential volume of pipeline debris along the entire length of the pipeline.

Evaluate the efficiency of production cleaning pigging strategies with regard to pig type and run frequency.

Evaluate the performance of standard and or specialised cleaning pigs.

Evaluate the effectiveness of chemical cleaning programs.

Provide a “Go/No Go” indicator before running an ILI tool.

Evaluate the efficiency of pre-inspection cleaning programs, before, during and after implementation.

Develop “intelligent cleaning” programs where routine measurement of actual pipeline conditions can be used to optimise pipeline healthcare strategies.

10”- Advance Geometry Tool

12”- Advance Geometry Tool

16”- Advance Geometry Tool

18”- Advance Geometry Tool

20”- Advance Geometry Tool

24”- Advance Geometry Tool

30”- Advance Geometry Tool

36”- Advance Geometry Tool

48”- Advance Geometry Tool

Rest sizes can be made available on demand.

Trained Engineers (Level-II) with hands on experience of more than 8 years in running of Advance Geometry Tools and inline inspection tools with 3000 Km of inspection under their belt. They are capable of

Onsite tool preparation and calibration

Onsite trouble shooting and problem solving

Supervision of tool running operations, tool tracking assistance

Onsite reporting

Onsite Dig verification

Trained Data analyst (Level-II) with over 8 years of experience and over 10,000 km of hands on data analysis experience on geometry data analysis, inline inspection data analysis with QC certified. They have experience in seeing the data and also involve in onsite dig verification services which makes their analysis that more reliable and accurate. They are capable

Most accurate and reliable analysis of available data

Fast turn around of reports

Provide assistance in preliminary reporting

Assistance on onsite dig verification

Final report predation

Report presentation as required

The DuctRunner™ inertial mapping technology fundamentally consists of 3 major components:The Orientation Measurement Unit (OMU) contains all inertial sensors as well as a range of secondary sensors. The OMU is carefully calibrated to determine the alignment of each mechanically assembled sensor to within 0.01°.

The OMU is fully autonomous, i.e. it is battery powered and the data logged is stored internally during a measurement run. This eliminates the need to drag a data and/or power cable behind the system. Also, autonomy means that it does not need to be traced above ground as it moves through a pipe and thus can travel to any depth and underneath any obstacle (such as rivers, railways, highways, buildings etc.).

An application specific housing and centralizing system that typically contains the odometers to record the speed of travel.

Proprietary X-Traction® and X-View® data processing software.

These software programs convert the autonomously logged data by the OMU and odometers to an accurate 3-dimensional line in the same coordinate system as the given coordinates at the entry and exit points.

Impex Technology Import, Export services , Industrial, pipeline pigging services, is committed to excellence in every way, in our work ethic, in the products and services we provide,

Contact now© 2023 Impex Technology. All Rights Reserved Designed & Hosted By Web universals | Sitemap